SERVICEs

Powder Coating Services

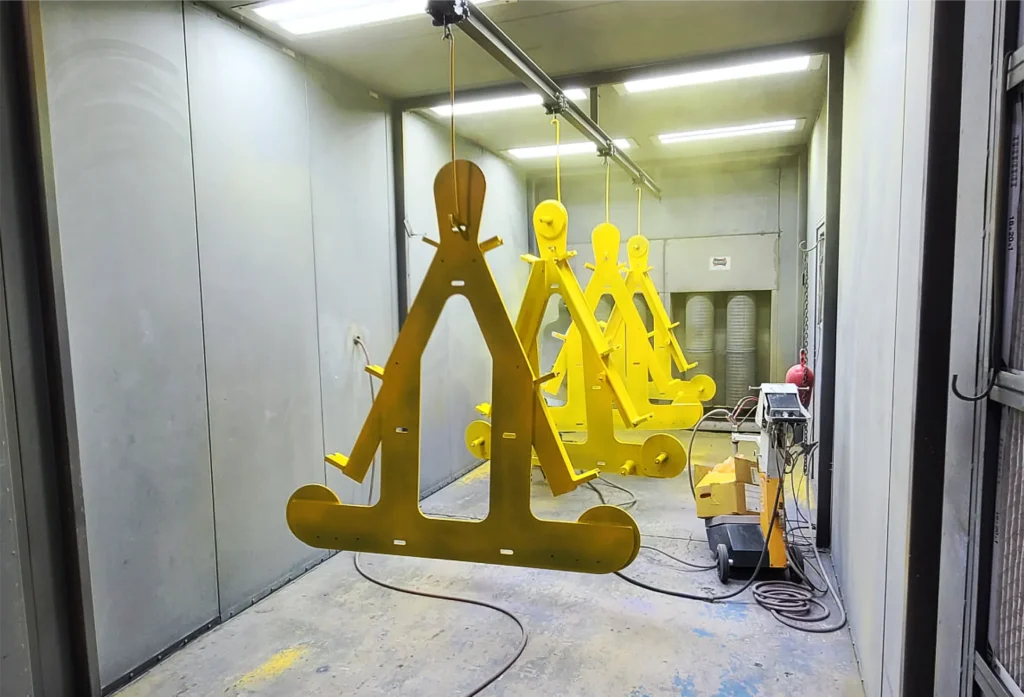

Powder coating is a cutting-edge finishing technique known for its durability and superior quality. This process involves electrostatically applying a dry polymer-resin powder to a metal surface, which is then baked to create a chemical bond. The result is a finish that is highly resistant to wear and breakdown, offering long-lasting protection and a sleek appearance.

Widely recognized as an eco-friendly and durable alternative to traditional paint, powder coating is popular across various industries for both consumer and industrial applications, thanks to its exceptional performance and versatility.

Colombo Powder Coating Curing Oven

Our state-of-the-art paint booth and powder coat curing oven are among the largest in the region. Our paint booth measures over 20’ (L) x 10’ (W) x 10’ (H), and our sandblasting booth measures 21′ (L) x 18′ (D) x 10′ (H). This expansive capacity enables us to handle a wide range of coating projects, from individual consumer items and batch parts to large industrial structures and machinery.

Reach out to us for more details or to schedule a tour of our facility—we’d be happy to show you our capabilities in action!

Sandblasting

A great finish starts with a barrier-free surface. To achieve this, we offer a unique pre-cleaning process as well as traditional sandblast capabilities. Specializing in sandblasting, it provides a professional and cost-effective solution for removing rust, paint, coatings, body filler, and grease from nearly any material.

Our gentle and affordable process effectively eliminates old finishes and corrosion without compromising the integrity of the surface. We use plastic media for stripping old finishes and glass bead blasting for rust removal. These methods are both efficient and environmentally friendly, avoiding the harsh chemicals and potential surface damage associated with traditional sandblasting.

Sandblasting is an efficient way to remove old finishes.

- Our sandblasting Booth 12 feet by 24 feet by 10 feet tall.

- We also can do small parts in our smaller blast booth

- Larger parts are done in our main booth

- Examples of large parts included large car frames, handrails up to 20 feet long

- We have done large spiral staircases, large steel plates, big racks etc.

Before blasting smaller parts, we place them into a small oven that is used to burn off paint, oily parts and prep them for sandblasting the oven size is 4 feet cube